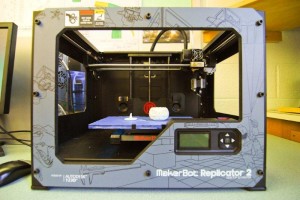

TOWAMENCIN – The next wave in design technology has arrived in H-Pod. The Technology & Engineering Education Department added the Makerbot Replicator2 to its tool kit. The printer (think hot glue gun on and x.y.z axis) is capable of building a three dimensional object from any computer model. Some objects take as little as 30 minutes to build while others may take as long as 12 hours. The printer extrudes PLA (polylactide) filament that is heated to 230° C which then rapidly cools to the touch in moments.

Students in Mr. Curt Reichwein’s Mechanical Drawing course are using this new technology to design, create and build air-powered balloon cars. Reichwein said the challenge “is to design build and create a vehicle that will be powered by a balloon that will be built and raced against each other. Students will run through mass properties analysis, including weight, volume, and the amount of material consumed while trying to create the lightest vehicle that travels the fastest and furthest. Students will also compete in the people’s choice award category for best visual design.”

Senior, Michael Zawacki, is close to finishing his design. He said the most enjoyable part of the project was “taking an idea and…watching it become a physical thing instead of just thoughts in your head.” Michael’s design currently resembles the land speeder from Star Wars. After high school, Michael plans on studying video game design at Drexel.

Ryan Phung, NPHS junior, said, “after seeing my first design in its physical form, I could have done a way better job. I reworked my thinking.” In the end, Ryan feels confident in his design, although he continues making changes to it. However, 3D printing isn’t limited to balloon toy cars.

This technology has potential to revolutionize the medical industry. The concept of growing organs is getting closer, but there are hurdles to overcome. “Bioengineers from the University of Pennsylvania have turned the problem inside out by using a 3D printer called a RepRap to make templates of blood vessel networks out of sugar. Once the networks are encased in a block of cells, the sugar can be dissolved, leaving a functional vascular network behind” (upenn.edu). Universities and High Schools across the country are using this technology to unlock and discover new solutions to old problems that were previously unsolvable.

Currently, the main entrance to the IMC has an extensive display of 3D printed objects in their display case. There are many objects on display including, magazines, microcontrollers, student projects, and more. If you would like to take a course that uses these printers, sign up for Mechanical Drawing, Introduction to Engineering Design, or Computer Integrated Manufacturing Systems. Students are currently using one printer in class, but more printers are on their way thanks to a grant from North Penn’s Education Foundation. If you had one, what would you make?

http://www.upenn.edu/spotlights/rep-rap-3d-printing-blood-vessel-networks